Please note this was written in the fall of 2023 so some information is no longer correct or relevant. Several edits have since been made to clarify the status in spring 2025. Here is a link to our more recent blog on this topic: https://proto-pasta.com/blogs/press/protopasta-spools-are-bambu-ams-compatible

You too can print with Protopasta on Bambu printers for a beautiful result!

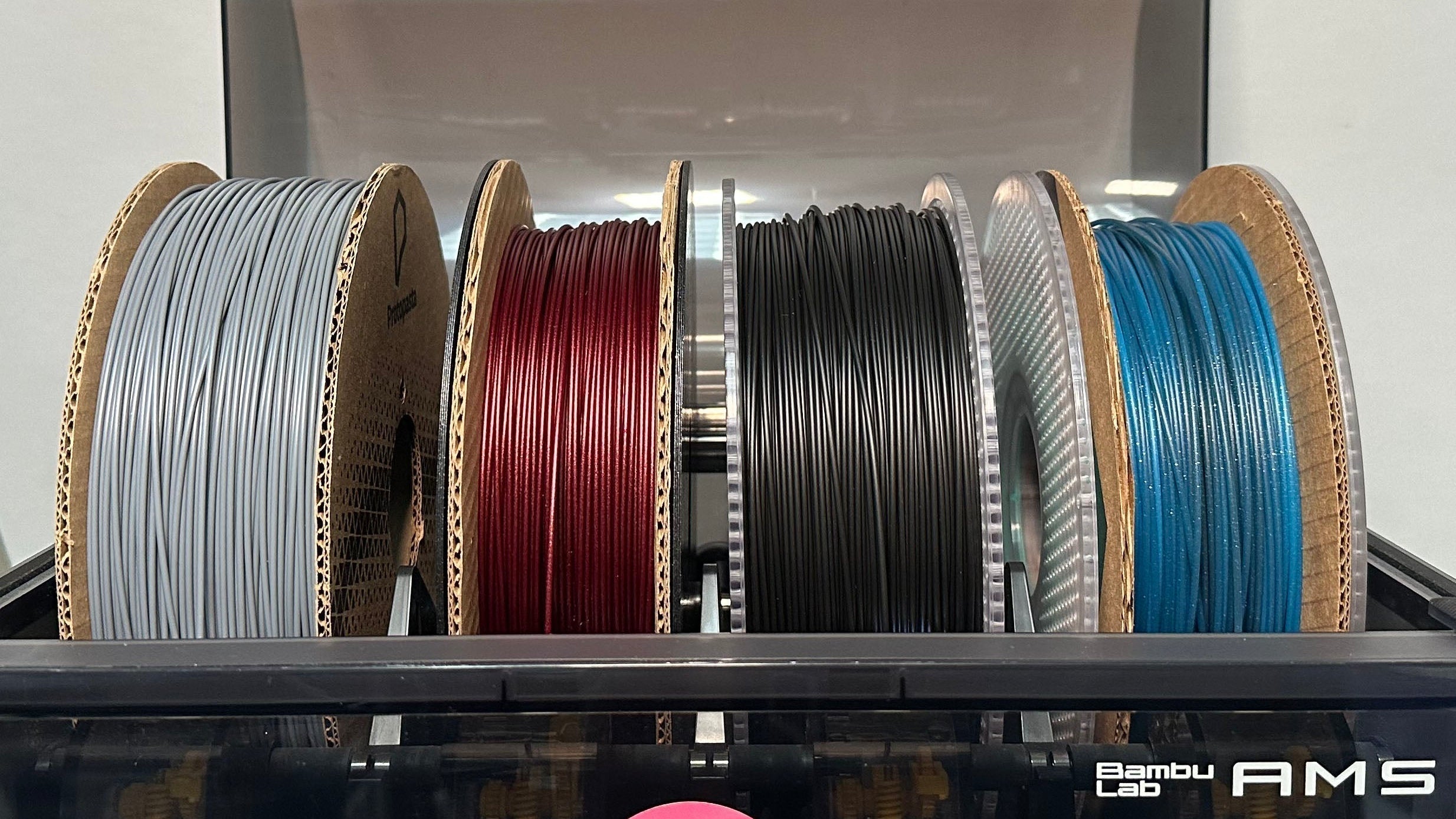

Bambu Lab has been improving the FDM 3D printing experience with the introduction of their printers over the last year. These machines are closer to living up to their hype than most others, and the folks here at Protopasta have enjoyed the incredible speed and reliability of these machines. We also have liked playing with the novelty of multi-color prints using the AMS with the P1S and X1 Carbon. And we've gained some experience since our first Bambu blog.

While in our opinion the AMS is the least polished part of the Bambu ecosystem and still has that "is it going to make it!?" feel of 3D printers of the past, it opens up possibilities for multi-color prints that were previously much less reliable than this solution. Below is a multi-color PLA print done entirely in Protopasta PLA with stock (in 2023) 8 inch corrugated spools.

Pikapool - Printed Using AMS with Protopasta Corrugated Spools

The main thing that makes us sad about the AMS is that the Bambu user manual states that the system is not compatible with carboard spools. We understand. The AMS is a complicated piece of equipment where everything must go right hundreds of times in a single print, and Bambu wants to minimize issues.

That said, we've found that in most situations, Protopasta corrugated cardboard spools work well. Here's our latest understanding:

AMS Issue #1 - Designed for 200 mm spools, not 8 inch spools

Our old spools were 8 inches (203 mm) in diameter which unfortunately do not fit in the AMS with the lid closed. If you set the lid on the little tabs provided for latching it, the lid has a place to rest and the spools fit! Sure, the lid is not sealed, but in our experience, Protopasta PLA and HTPLA still print well.

We reduced the diameter of our corrugated spool sides 203 mm to 199.5 mm. These will fit in the AMS with the lid closed. Being a tiny bit smaller than a Bambu plastic spool also has some advantages we'll touch on later. In the meantime, Thingiverse user PaulTheSimon created this thing to cut 8" cardboard spools to make them smaller.

AMS Issue #2 - Cardboard particles?

So far, this has not been a problem at all, even when printing long multi-color prints. There might be a tiny dusting on the rubber rollers, but nothing that affects function in our experience. We just keep printing awesome multi-color prints. Vacuum periodically or consider a spool edge guard (like this) that does not make 1kg spools wider than 68 mm or more than 202 mm in diameter.

AMS Issue #3 - Cardboard spools are light

Our corrugated spools are very light, weighing between 75 g and 95 g. This is fantastic! It reduces our shipping costs (and yours) and our carbon footprint, substantially. Unfortunately, the AMS does not love it when the spools are nearly empty. This has not been a huge issue for us, but the spools can pop up when retracting. Setting the AMS lid down onto the tabs (like above) helps. Adding weight to your spool can also help.

AMS Issue #4 - Damaged edges

Yes, this is a thing. If the corrugated spool is dropped, or if there are hundreds of material changes in your print, there could be retraction issues because the corrugated edge is damaged. In this case, you can remove the damaged side and glue on a replacement with this printable guide or transfer to a reusable spool like shown below.

AMS Issue #5 - Filament interferes with feeder (old 8" spools only)

This is only an issue with our old 1 kg spools. The combination of our sides being 8 inches and our cores (the inside of the spool where the filament is wrapped around) being larger than most vendors, the filament is fairly close to the spool edge. With a full 1 kg spool, the filament can touch the feeder. We don't love it, but mostly, it is OK. If there are a lot of material changes with a new 1 kg, we recommend keeping an eye on it while we are working to resolve this permanently with a new (now current) core and side size (more below).

AMS Issue #6 - Filament not affixed to spool (updated)

In every other printer we know of, including the Bambu without an AMS, the spool is not mechanically rotated independently from the filament by an external motor. Because this is done in the AMS, when a spool is nearly empty, it is theoretically possible for the filament end to come unaffixed from the core, which confuses the AMS. Our core notching contraption makes a half-circle cutout in the core, where the filament end goes through and grips so that we can then wind. By putting a piece of tape on the filament end where it sticks through the core, this issue for nearly empty spools can be eliminated. Since writing this we learned this is not preferred when running out of filament.

What has Protopasta done to address these issues?

Fortunately, current Protopasta spools work well as-is! Still, to give folks a better experience and more options, we are making changes to our spools in the coming months. We are rolling these out in a way that minimizes waste and chaos. This will take time so thanks in advance for your patience. Here's what to expect:

First, we modified the corrugated spool sides to be 199.5 mm in diameter. Second, we reduced the core diameter of 1 kg spools. (done in 2023)

Update: Our newest spools no longer have perforations, but the center can be cut out with a 3D printable cutting guide (download here) in combination with a standard #11 X-ACTO blade like seen below.

With these modifications, the following features are unlocked-

- The AMS lid can be fully sealed with unmodified Protopasta spools

- New, full, 1 kg spools will no longer interfere with AMS feeder

- By cutting out the center in the spool side and printing a small part, a Bambu plastic spool can be used with 500 g offerings without spool side removal.

- Bambu Reusable spool sides can be installed in a similar fashion to master spool coils on Protopasta 1 kg's by removing the sides.

You can always opt for a spool edge guard instead for some protection without spool modification, just be careful not to exceed the 68 mm maximum spool width for AMS.

Installing 500g Protopasta spool onto Bambu Reusable Spool

**NOTE** All 500 g spools have 199.5 mm spool sides expect any remaining here.

With the new spool sides, the Bambu Reusable Spool can be installed onto Protopasta 500 g corrugated spools. This process is pretty simple, but does require a hobby knife and a 3D printed spacer which you can download and print for yourself.

Steps as seen in the below video:

- Print the cutting guide.

- Cut out center circle to larger diameter along perforations.

- Tape the filament end inside core (if desired).

- Print out the adapter, and install on the correct side.

- Snap together the Bambu Reusable Spool.

What is the point of the adapter? First, the space created by this adapter is just right for the little "fin" that is in the bottom of the AMS. Second, it mechanically connects the 2 spools together so the AMS can pull filament with the spool.

Installing 1 kg Protopasta spool onto Bambu Reusable Spool

**NOTE** All 1 kg spools have 199.5 mm spool sides expect any remaining here.

With the new spool sides, the Bambu Reusable Spool can be installed onto Protopasta 1 kg corrugated spools. This process is a bit trickier than the 500 g version because the spool sides must be removed from the core, leaving the filament unprotected. While this is possible, proceed at your own risk!

Steps:

- Cut out center circle to larger diameter along perforations on the side of the Protopasta 1 kg where the filament pokes through the core. This step is so the glue on the inside of the core can be trimmed away to make sure the Bambu Reusable spool fits nicely into the core, it is just the right size.

- Trim the filament end so it does not poke out into the core and tape filament end (if desired). The filament must not sit on top of the core, the Bambu reusable spool need to sit tight there.

- Install the Bambu Reusable spool side that has the indexing notch to connect the core to the spool mechanically.

- Cut the center out and trim the glue of the other side.

- Tear off other side, and complete assembly.

Now you can print with confidence using Protopasta with Bambu's AMS, but if ever you have questions or concerns, don't hesitate to contact us. And don't forget to share all your beautiful prints with us as well. We love to see them!

Happy printing,

Dustin and the Protopasta Team