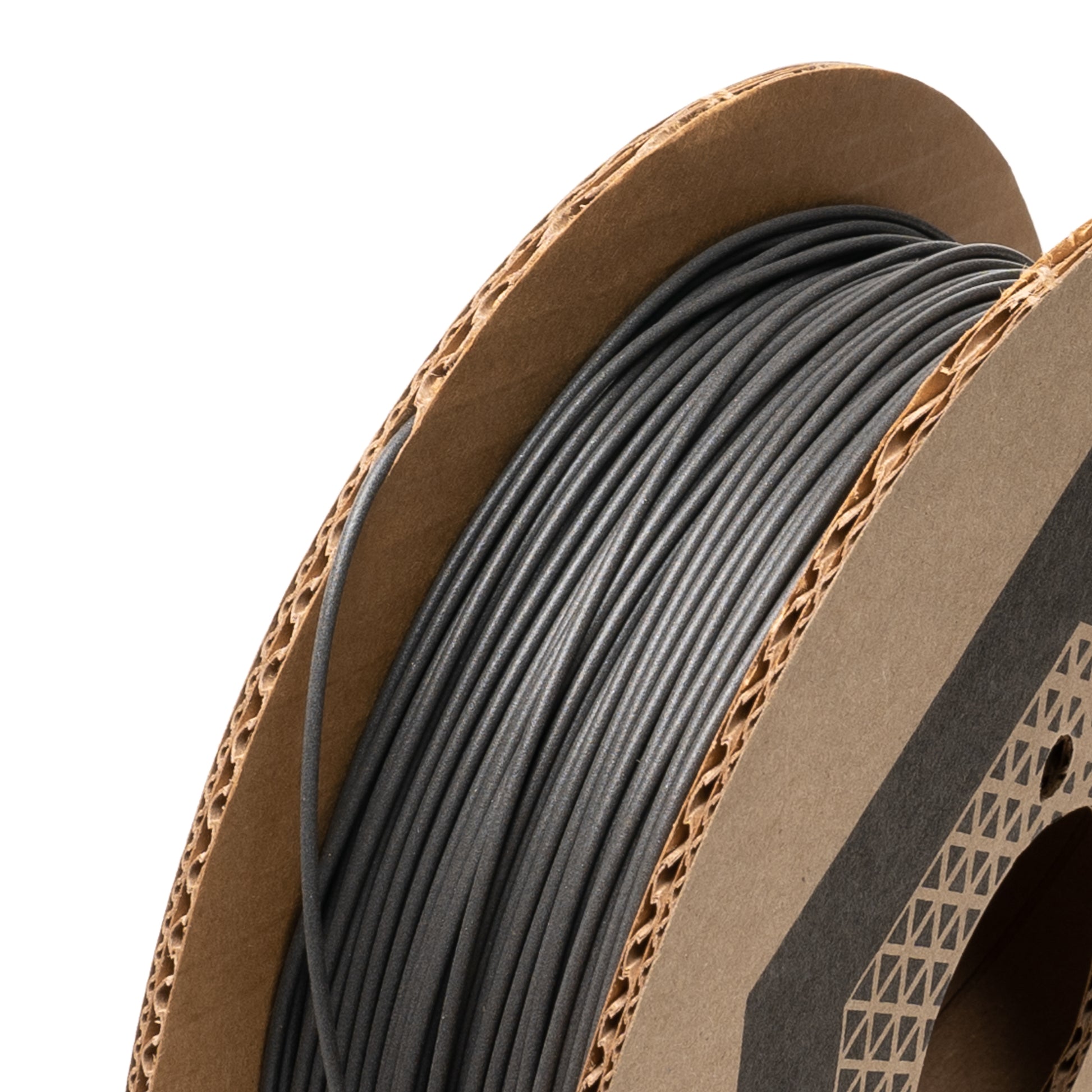

Iron-filled Metal Composite PLA

SKU: FEP11710

Now available in 1kg size.

Prints like PLA, behaves like metal! Experience our most "attractive" material yet!!!

Protopasta Rustable Magnetic Iron Metal PLA Composite is actually ferromagnetic. It responds to magnets and behaves similarly to pure iron! Encapsulated in plastic, the iron maintains a stable matte, cast-metal finish as printed, but can be rusted when desired.

More product specific details and application ideas for our Rustable Magnetic Iron Metal PLA Composite can be found below.

Technical Data Sheets

Technical data sheets available for download here.

Safety Data Sheets

Safety data sheets available for download here.

Shipping

We provide a number of domestic shipping options within the United States via UPS, including free shipping on orders of $50 or more. We also provide international shipping via DHL Express.

Returns

At ProtoPlant's discretion, returns and replacements will be accepted within 90 days of purchase. Please check the material label before opening your product. Only sealed product can be returned. Shipping of items for exchange or refund is paid by the customer. More information about returns and replacements can be found in our terms and conditions.

Prints like PLA, behaves like metal! Experience our most "attractive" material yet!!!

Proto-pasta Rustable Magnetic Iron Metal PLA Composite is actually ferromagnetic. It responds to magnets and behaves similarly to pure iron! Encapsulated in plastic, the iron maintains a stable matte, cast metal finish as printed, but can be rusted when desired. Here is why Proto-pasta Iron PLA is so interesting:

- Weighted feel with 1.5x the density of standard PLA

- Rustable to create modern artifacts in a few easy steps - instruction here

- Attracts magnets (neodymium type recommended for strongest attraction)

- More thermally conductive than standard plastic

- Prints easily like PLA with less nozzle wear than Steel or Carbon Fiber

- More filament for your money - 2x the length of Bronzefill (500g Iron =1kg Bronzefill)

We recommend experimenting with creating a rusty patina like this:

**This filament is more abrasive than standard PLA. Be prepared to replace your nozzle and do 1st layer adjustment. Try a wear resistant and/or larger diameter nozzle for increased service intervals.

- Available in 1.75 & 2.85 (3) mm diameters.

- 125g are loose coils, 500g is on a 8" diameter spool, 2kg is on a 12" diameter spool.

- Usable on most PLA-compatible printers, such as Lulzbot, Makerbot, FlashForge, Dremel, Ultimaker, Printrbot, and more!

In filament form, FEPLA is slightly more brittle than standard PLA, and requires extra care when handling.

Processing is comparable to standard PLA. No heated bed required. Process may be less consistent on smaller nozzles and/or bowden type machines. We frequently print using direct-drive systems with 0.4 mm nozzles, though prefer 0.6 mm and 190-210C (standard PLA or a bit cooler) for the best experience.

Characteristics

- Weighted feel with 1.5x the density of standard PLA

- Rustable to create modern artifacts in a few easy steps - instruction here

- Attracts magnets (neodymium type recommended for strongest attraction)

- More thermally conductive than standard plastic

- Prints easily like PLA with less nozzle wear than Steel or Carbon Fiber

- More filament for your money - 2x the length of Bronzefill (500g Iron =1kg Bronzefill)

Applications

- Faux brick or stone

- Fixtures or hardware

- Knobs or buttons

- Heat sinks or exchangers

- Fine art & sculpture

- Emblems, signage, or trophies

- Jewelry, like pendants or bracelets

- Cosplay, game pieces, or figurines

Material Data

- Base resin: PLA

- Additive: Real Iron Powder

- Particle size: less than 250 micron (0.25mm)

- Odor: low or no

- Density: Approx. 1.85 g/cc

- Length (500g): 97m (1.75mm) and 36m (2.85mm)

Printer Settings

- Speed: 10-20 mm/s 1st layer, 20-80 mm/s rest of part

- Nozzle Set-point: 185-215C (hottest on 1st layer for best adhesion)

- Nozzle Actual: maintain set-point, reduce speed if less than

- Nozzle Type: Standard or wear resistant for extended use

- Nozzle Diameter: 0.6mm or larger preferred, 0.4mm okay with 0.25mm minimum for experts

- Layer thickness: 0.15-0.20mm recommended for a balance of quality, reliability, and productivity

- Bed Temperature: Room-60C (over 60C can worsen warp)

- Bed Preparation: Elmers purple disappearing glue stick or your other favorite PLA surface preparation

This material has been flow optimized and has less moisture uptake than standard PLAs, however composites are still sometimes more tricky to print depending on hardware and software settings. The main challenge is to keep mass flow up (larger nozzle + fast speed) and in a single direction (minimal retraction) to avoid heat soak. More on that topic here.