Carbon Fiber HTPLA can make very accurate parts particularly when heat treating, demonstrating less distortion of form and dimension change after heat treating compared to other HTPLAs. This characteristic is particularly useful when seeking to create application-specific parts where exceptional accuracy, high stiffness, or use up to 160 C is required.

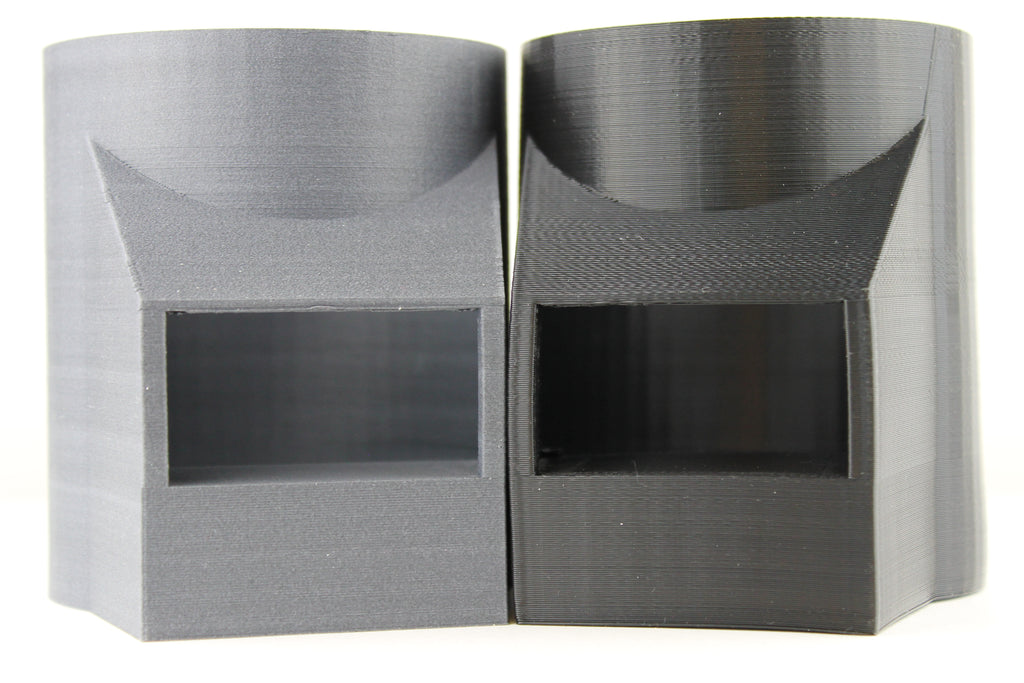

Above is an example of how well heat treated Carbon Fiber HTPLA (left) holds form compared to our opaque black HTPLA (right). Holes are round and surfaces are flat, straight, and true with Carbon Fiber. Standard HTPLA (right) shows significantly more distortion. Knowing heat treated CF parts can hold form opens up applications where accuracy and form are critical.

Before going further, please consider our article on tuning your printer for Carbon Fiber HTPLA, then let's explore how to process and adapt your prints to take full-advantage of HTPLA's heat resistance and stable from. You may want to determine your own condition-specific scale factors, but let's start with our example scale factors and consider how to adjust scale for more accurate size.

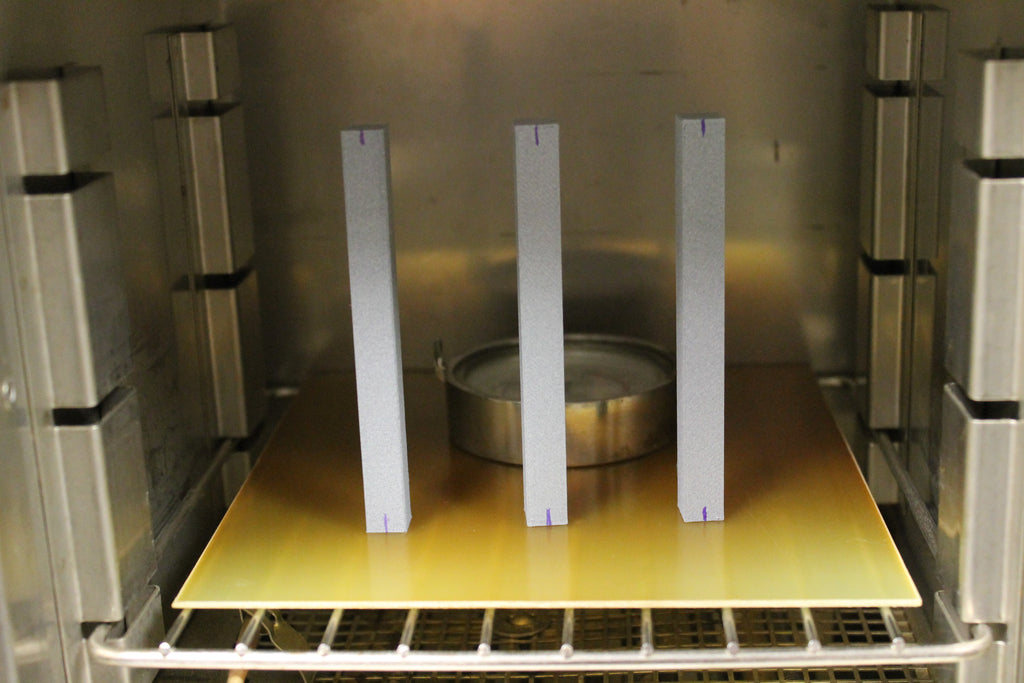

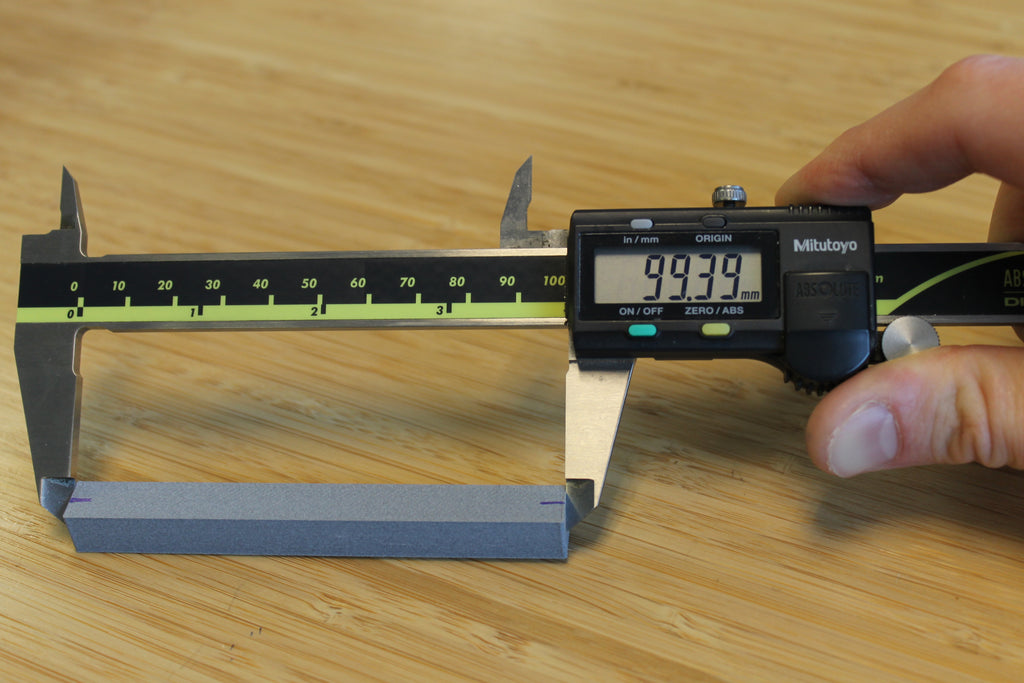

We printed 100 mm length bars in x, y, and z, then measured the result. We then heat treated these parts in our lab oven at 110 deg C (220 deg F) for 30 minutes. Please don't get too stuck on these specific conditions as a variety of temperatures and times can yield acceptable results. When back at room temperature, we again recorded the dimensions of the heat treated bars for comparison.

Notice that we marked our bars to be sure we measured in the same location to minimize measurement error. Measuring in a different location (corners or bottom) can yield results 0.2 or even 0.4 mm larger. Measuring in a consistent location, we found shrinkage of about 0.6% in x/y and growth of 1.0% in z.

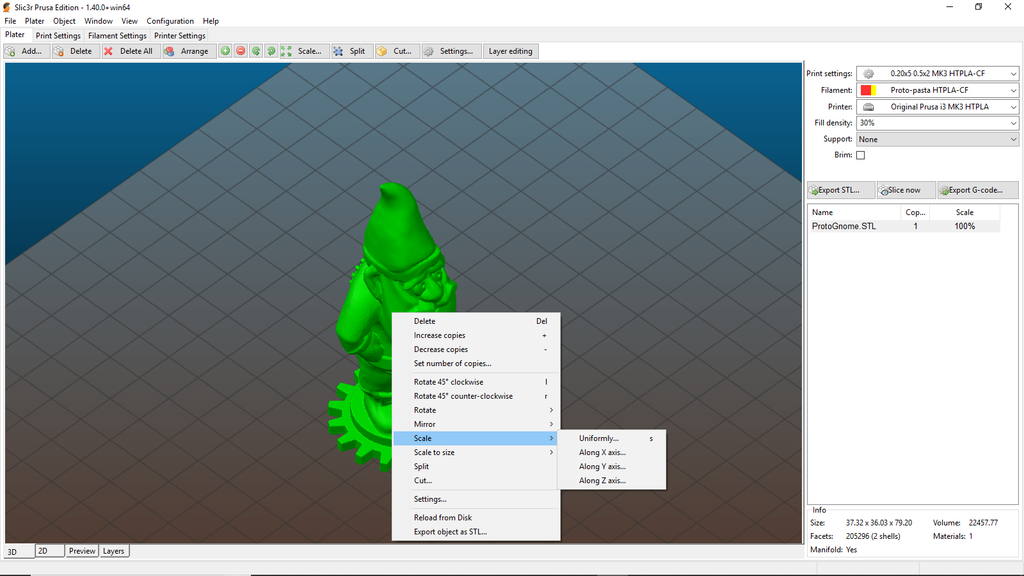

To compensate, we can scale our parts to 100.6% in x/y and 99% in z inside our slicer program. These values are based on our specific conditions defined by hardware, settings, geometry, and environment. You may choose to find different scales for your conditions, but your scale factors don't need to be exact. An error of 0.1% in scale on 100 mm is only 0.10 mm. For typical part sizes, tenths of % error is likely less than other errors your printer introduces.

Heat treating may be new to you, but with a few simple steps, you can make heat resistant parts that are true to size after heat treating! Don't have any Carbon Fiber HTPLA? Get some here to follow along and find out what's possible.